Take home message

Shop milk is either pasteurized or UHT treated. In a study on the effects of heating, various indicators were assessed, such as functional enzyme concentrations, concentrations of different milk proteins, and various vitamins. Particularly in the whey proteins and enzymes, there is a clear decrease in concentration and / or efficacy with increasing heating. The B vitamins are not changed through heating. The largest differences are between raw milk and UHT milk.

Types of shop milk compared

A study by the milk research institute in Bern-Liebefeld (CH) evaluated the impact of thermal treatment on the most important milk components (Blanc, 1980). Five treatments were compared: (1) unprocessed raw milk, (2) pasteurized milk (HTST; 72oC, 15 sec), (3) highly pasteurized milk (92oC, 20 sec), (4) UHT direct (150oC, 2 sec) and (5) UHT indirect (141oC, 14 sec under pressure). Milk was examined monthly, during the period of 1 year. The milk origin was always from a local small creamery. The averages of the values are presented here (n = 12).

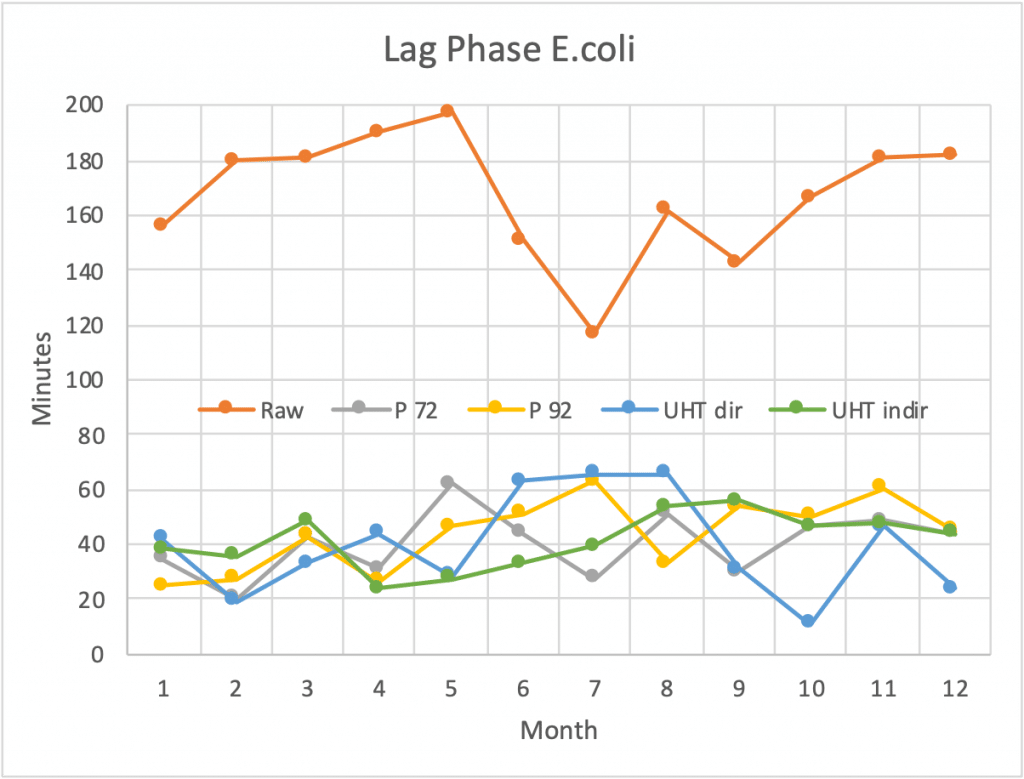

Blanc studied different milk components, such as vitamins, enzymes and several protein concentrations. Most results are fairly unambiguous and mainly show the effect of increasing heating. In several results, there is an additional seasonal effect, indicating that heating outcomes can be different in summer than in winter. An example of the heating results is the lag phase of the growth of Escherichia coli (Figure 1). The lag phase indicates for how long the growth of bacteria are suppressed. The longer the lag phase, the better the milk’s defense systems. Two outcomes are striking, namely, firstly, that with each heating (2-5) the lag phase is shortened to a quarter of the time of raw milk. This indicates that after heating of milk the risk that potentially disease-causing (pathogenic) bacteria will multiply, is increased. Furthermore, there is a seasonal effect; the resistance in the raw milk against pathogenic bacteria is higher in winter than in summer milk.

Declining concentrations after heating

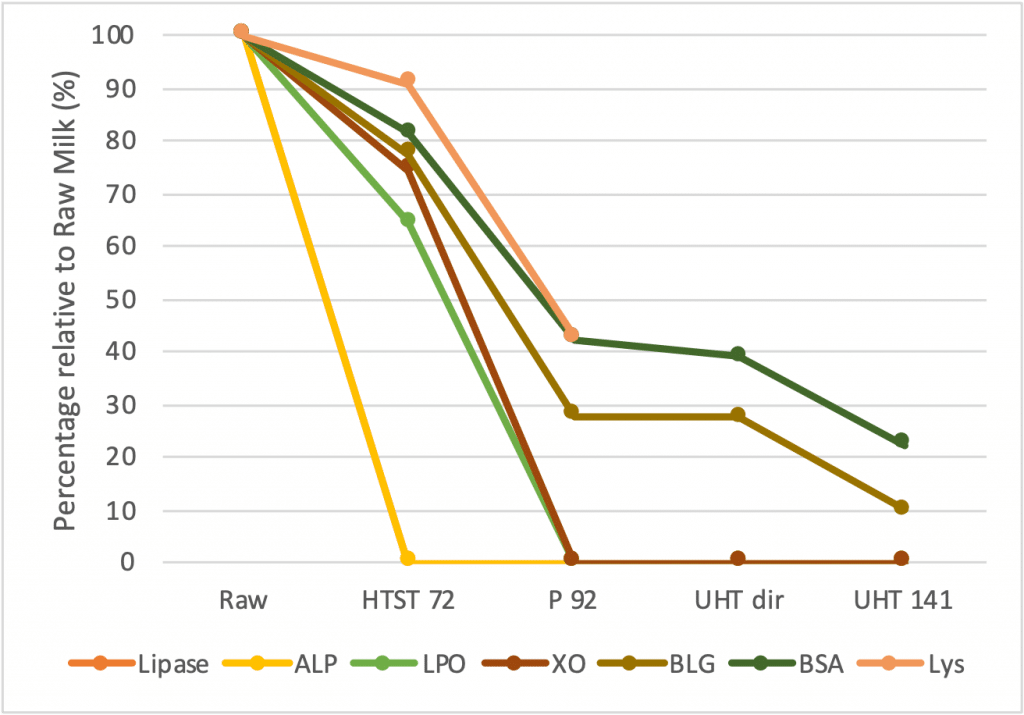

A range of milk components showed decreased concentrations after heating. For each component the value in raw milk was set at 100% and the relative decrease (due to denaturation) was calculated with respect to raw milk. The averages of the 12 months (January – December) are shown (figure 2) for several enzymes: Lipase, Alkaline Phosphatase (ALP), Xanthinoxidase (XO), as well as three whey proteins: Beta-lactoglobulin (BLG), Bovine Serum Albumin (Albumin) and Lactoperoxidase (LPO).

Lipase and ALP completely disappeared after each step in heating (the two lines are overlapping). Loss of ALP is used as an industrial indicator that milk has been pasteurized and inactivated above 62-63oC. Lipase is the enzyme that takes care of the fat digestion. XO is an enzyme that is used as an indicator for the higher pasteurization levels and is therefore no longer active in treatments (3) – (5). The whey proteins loose their functionality when the heating is at a higher temperature and the heating time lasts longer. Although the LPO concentration was not measured at UHT temperature, it is assumed that the value is close to zero. A measurable effect is therefore already visible from all measurements with the HTST treatment.

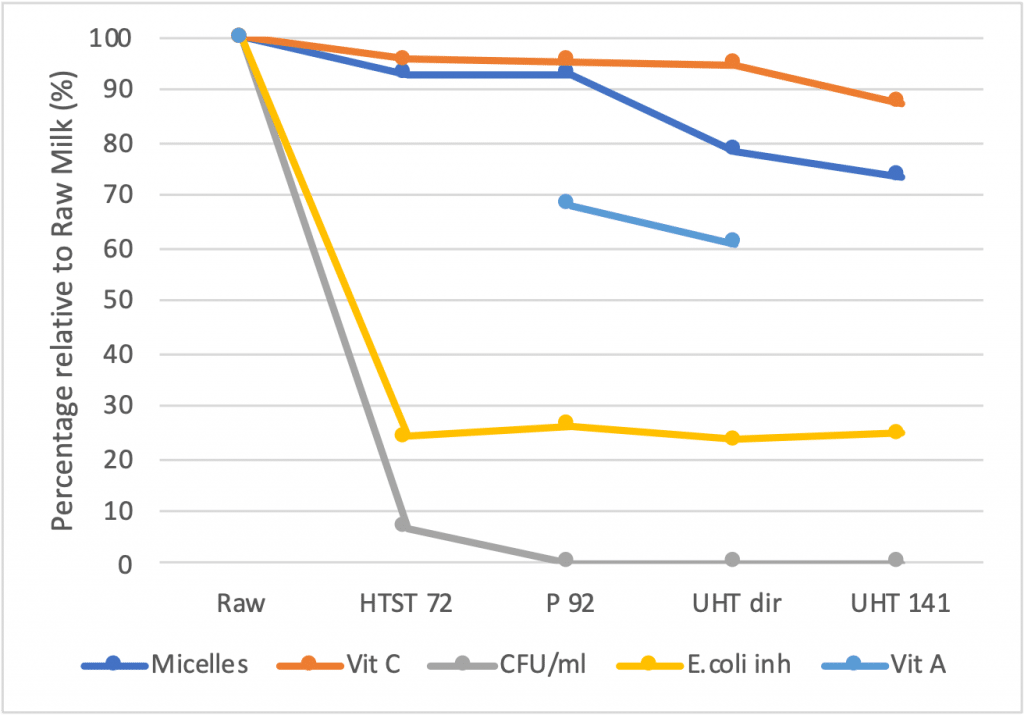

Figure 3 shows the concentration of vitamins A and C, the total plate count of bacteria in milk, the lag phase for the growth of E. coli and the casein micelles (colloidal particles in solution). Vitamin A was not measured at every temperature, but its concentrations decreased sharply. Vitamin C decreases slightly, especially at the higher heating temperature. The main purpose of a heat treatment is, the reduction of the number of bacteria. The plate count of raw milk was approximately 20,000 bacteria per ml. After HTST pasteurization a sharp drop was seen, although not to zero, and after UHT treatment all bacteria disappeared. The differences in bacterial count are the main reason that HTST milk is stored in the refrigerator with a shelf life of 7-10 days, while the UHT milk is stored outside at room temperature with a shelf life of approximately 3 months. Both bacteria and its spores are completely destroyed by the UHT process. It has already been described above that after heating milk, pathogenic bacteria can easily grow out. In raw milk there is a certain defense mechanism against bacterial growth, that no longer works in shop milk. However, this defense mechanism is insufficient to protect raw milk against any form of bacterial growth over longer time periods.

Unchanged substances after heating

Blanc (1980) measured several B vitamins (B1, B2, B3, B6) and could not find significant changes in concentration after heating. The same applies to the measured amino acids, as well as the summed content of amino acids. However, fluctuation in some of the vitamin concentrations throughout the year was found, likely related to the diet of the cows.

Increasing concentrations after heating

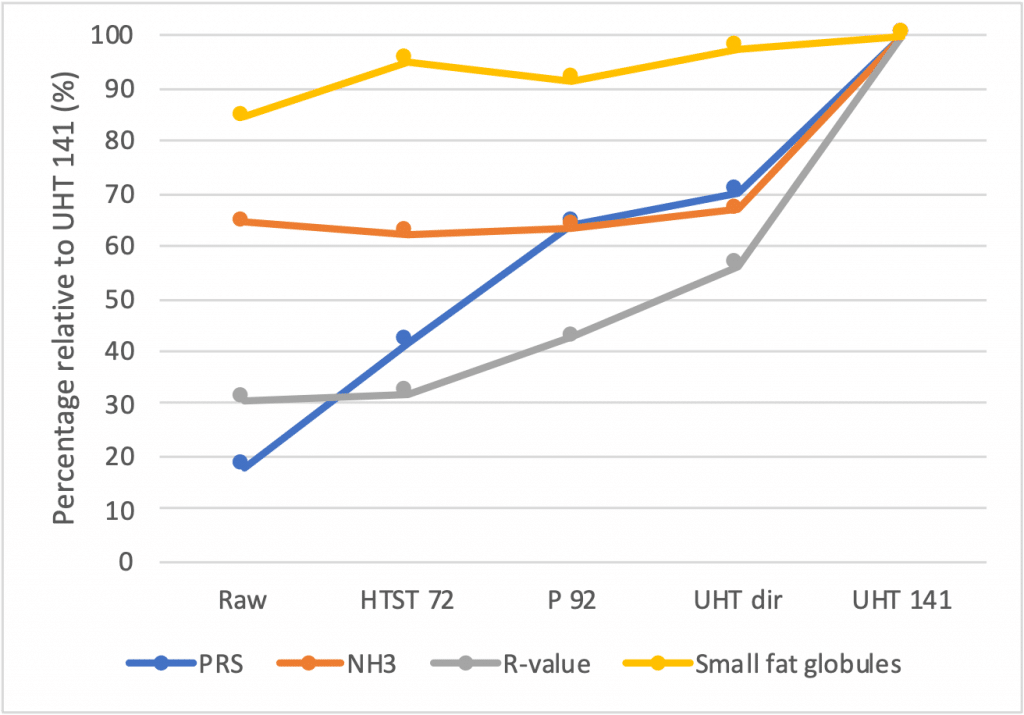

In Figure 4, four values are increased after heating. In contrast to the previous figures, the UHT treatment is now set at 100% instead of the raw milk. The PRS (protein reducing substances), the content of free ammonia and the R-value increase, especially at higher heatings. The PRS value is a measure of the reduction capacity of the casein. An increasing content of free ammonia is related to increased protein breakdown. The R-value is a measure of the clumping of the casein after the addition of rennet. Finally, the proportion of small fat globules increases (in the size of 1-2 mu-meter), which is related to the homogenization of the heated milks.

All graphs are derived from: B.Blanc. Einfluss der thermischen Behandlung auf die wichstigsten Milchinhaltstoffe und auf den ernährungsphysiologischen Wert der Milch. Alimenta-Sonderausgabe, (1980), pp. 5-25.